Meat slaughter and processing equipment play a critical role in the transformation of livestock into various meat products. This process involves a range of machinery and tools designed to ensure the safety, quality, and efficiency of meat production. In this topic cluster, we will explore the different types of equipment used in the meat industry, their functions, and their significance within the realms of meat science and the food & drink industry.

The Slaughter Process

The beginning of the meat production journey starts with the slaughter process, which involves stunning and bleeding techniques to render the livestock unconscious and stop blood circulation. To achieve this, several pieces of equipment are used, including stunning devices such as captive bolt pistols, electrical stunning equipment, or gas stunning systems, which are designed to effectively stun the animal before the bleeding process. This step is crucial in minimizing the suffering of the animal and ensuring the quality of the meat.

Bleeding and Skinning Equipment

Following stunning, the animal is bled to remove blood from the body. This process is typically carried out using specialized bleeding equipment such as hoists, shackles, and conveyors that facilitate the movement of the animal for bleeding. Once the bleeding process is complete, skinning equipment comes into play to remove the skin from the carcass. Skinning machines and tools are designed to efficiently and hygienically separate the skin from the meat, contributing to the overall sanitation and quality of the meat products.

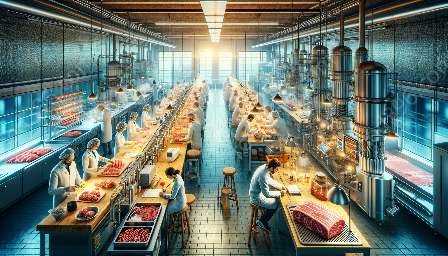

Cutting and Deboning Machinery

After the initial stages of slaughter, the carcass undergoes a series of cutting and deboning processes, where a variety of equipment is utilized. Bandsaws, circular knives, and meat slicers are some of the machinery employed in precision cutting to separate the carcass into primal cuts and further into retail cuts. Deboning machinery, such as automated deboning lines and meat trimmers, then play a crucial role in separating the meat from bones, ensuring minimal wastage and maximum utilization of all meat parts.

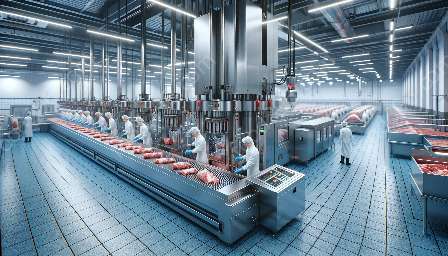

Grinding, Mixing, and Forming Equipment

For processed meat products such as sausages, burgers, and meatballs, grinding, mixing, and forming equipment are essential. This includes meat grinders, mixers, and forming machines that ensure the consistency and quality of the final product. These machines enable the thorough mixing of meat with spices, seasonings, and other ingredients, as well as the forming of the mixture into specific shapes and sizes, contributing to the appeal and taste of the processed meat products.

Packaging and Preservation Tools

Once the meat has been processed and prepared, packaging and preservation tools are employed to ensure the longevity and safety of the meat products. Vacuum packaging machines, shrink wrap systems, and sealing equipment help to securely package the meat, preventing contamination and extending its shelf life. Additionally, preservation tools such as smokehouses and curing chambers are utilized in the traditional preservation of meat products, infusing them with flavors and extending their storage capabilities.

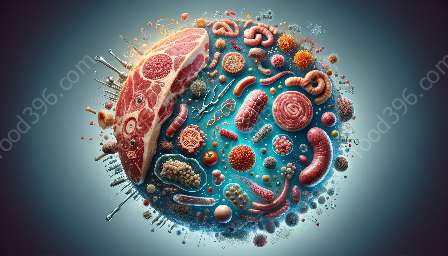

Significance in Meat Science

The utilization of advanced slaughter and processing equipment has a profound impact on meat science, influencing aspects such as meat quality, safety, and efficiency. The precise control and manipulation of the equipment's parameters contribute to the scientific understanding of meat processing, including the effects of different processing techniques on the microbial, chemical, and sensory properties of meat. Moreover, the use of state-of-the-art equipment also enables meat scientists to explore innovative methods for quality enhancement and preservation.

Impact on the Food & Drink Industry

The role of meat slaughter and processing equipment extends beyond the realm of meat science into the food & drink industry at large. It directly influences the production efficiency, product diversity, and overall quality of meat-based food products available to consumers. An understanding of the equipment used in meat processing is essential for food technologists, manufacturers, and chefs, as it shapes the landscape of meat-related culinary innovations and offerings in the market.

Conclusion

Meat slaughter and processing equipment form the backbone of the meat industry, driving the transformation of livestock into an array of meat products that cater to diverse consumer preferences. From the initial stages of slaughter to the packaging and preservation of meat products, each piece of equipment plays a vital role in ensuring the safety, quality, and efficiency of meat production. The significance of this equipment extends beyond its practical applications, influencing the realms of meat science and the broader food & drink industry, ultimately shaping the way meat products are produced, analyzed, and consumed.