Meat trimming and deboning are critical stages in meat processing, ensuring the efficiency of the entire production process. These techniques directly impact the quality and yield of meat products, making them crucial aspects in the meat industry. In this topic cluster, we will delve into the intricate art of meat trimming and deboning, their compatibility with meat slaughter and processing equipment, and the science behind meat preparation.

The Art of Meat Trimming

Meat trimming involves the removal of excess fat, connective tissues, and undesirable portions from meat cuts. It is a precise skill that requires extensive knowledge of meat anatomy and an understanding of the end product's specifications. There are various techniques used for meat trimming, including the use of specialized knives and tools specifically designed for this purpose.

Types of Meat Trimming:

- Surface Trimming: This method involves removing surface fat and blemishes from meat cuts without affecting the underlying muscles.

- Intercostal Trimming: It focuses on the removal of fat and tissue between the ribs, often required for rib-eye and strip loin cuts.

- Defatting: This process targets the removal of internal fat deposits within the meat, enhancing its overall leanness.

The effectiveness of meat trimming directly influences the appearance and palatability of the final meat products. Furthermore, it contributes to waste reduction and the optimization of meat yield, making it an essential skill in the meat processing industry.

The Precision of Deboning

Deboning meat requires dexterity and precision to separate the bones from the meat while maximizing yield and minimizing product damage. It is a delicate process that varies depending on the type of meat cut, as different anatomical structures necessitate specific deboning techniques. Whether deboning a whole carcass or specific cuts, the goal is to retain as much usable meat as possible while removing bones, cartilage, and connective tissues.

Common Deboning Techniques:

- Whole Carcass Deboning: Involves the separation of bones from the entire carcass, often utilized in large-scale processing facilities.

- Primal and Subprimal Deboning: Focuses on removing bones from major muscle groups, tailoring cuts to customer specifications.

- Customized Deboning: Adapts the deboning process to meet specific consumer demands, such as boneless or bone-in cuts.

Proper deboning techniques are crucial in optimizing meat yield and minimizing potential product defects. In addition, proficient deboning contributes to the efficient utilization of meat for various product lines, enhancing the overall value of the meat processing operation.

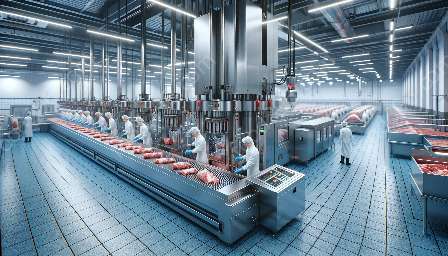

Compatibility with Meat Slaughter and Processing Equipment

Efficient meat trimming and deboning techniques are intricately linked with the utilization of appropriate meat slaughter and processing equipment. The seamless integration of these elements is essential for optimizing productivity, enhancing food safety, and maintaining consistent product quality. The following are key aspects of compatibility between trimming, deboning, and equipment:

Precision Tools and Machinery

Modern meat processing facilities utilize a wide array of precision tools and machinery designed to facilitate meat trimming and deboning procedures. These include specialized knives, slicers, bandsaws, and portioning equipment configured to accommodate varying meat cuts and processing requirements. The proper selection and maintenance of these tools are paramount in achieving efficient and accurate trimming and deboning outcomes.

Equipment Adaptability

Equipment adaptability plays a fundamental role in ensuring that meat processing operations can accommodate a diverse range of meat cuts and carcasses. Advanced deboning and trimming equipment are often adjustable to handle different sizes and types of meats, providing versatility and flexibility in processing operations. Additionally, the integration of automated technologies further enhances the precision and consistency of meat trimming and deboning processes.

Meat Science: Understanding the Anatomy

Meat trimming and deboning techniques are deeply rooted in the principles of meat science, which involves understanding the physiological and anatomical aspects of meat. This knowledge is essential for implementing effective trimming and deboning practices, ensuring maximum yield, product quality, and safety. Moreover, an understanding of meat science allows for the development of innovative techniques and processing methodologies.

Muscle Structure and Composition

An in-depth knowledge of meat science enables meat processors to comprehend the intricate muscle structure and composition of various meat cuts. Understanding the distribution of muscle fibers, connective tissues, and fat deposits facilitates strategic trimming and deboning, optimizing meat yield and texture. Furthermore, this knowledge aids in the creation of specialized meat products tailored to meet diverse consumer preferences.

Quality and Safety Standards

Meat science encompasses quality and safety standards that guide meat processing practices. These standards dictate the appropriate levels of fat and connective tissue in different meat cuts, ensuring that products meet nutritional, sensory, and food safety requirements. Through the application of meat science principles, meat processors can strive for continuous improvement in product consistency and compliance with regulatory standards.

Conclusion

Meat trimming and deboning techniques are intricate processes that significantly influence the efficiency, quality, and yield of meat products. The seamless compatibility of these techniques with meat slaughter and processing equipment, alongside a comprehensive understanding of meat science, is fundamental in achieving optimal results within the meat processing industry. By mastering the art of meat trimming and deboning, and integrating it with advanced equipment and scientific knowledge, meat processors can uphold high standards of product quality and innovation.