Butchery techniques are an essential part of the meat processing industry, combining centuries-old traditions with modern technology and scientific knowledge. In this comprehensive guide, we will delve into the intricate world of butchery, exploring the techniques, tools, and processes involved in turning a whole carcass into the various cuts of meat we find in our markets and on our plates.

The Art of Butchery Techniques

Butchery techniques have been honed and refined over centuries, with different cultures developing their unique methods of breaking down an animal carcass to maximize the usefulness of every part. The skill of a butcher lies in their ability to transform a whole animal into a diverse array of cuts, each with its own flavor, texture, and culinary application.

Traditional butchery techniques involve a deep understanding of anatomy, blade skills, and a keen eye for detail. The process begins with the breakdown of the carcass into primal cuts, such as the loin, rib, and shoulder. These are then further segmented into subprimal cuts, which can be tailored to the specific requirements of different dishes or customer preferences.

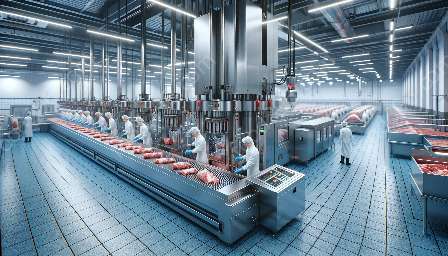

Modern butchery has also embraced technology, with the development of precision cutting machines and meat processing equipment that can streamline the process while maintaining quality and consistency.

Meat Slaughter and Processing Equipment

Meat slaughter and processing equipment play a critical role in ensuring the safety and efficiency of the meat production process. From stunning to bleeding, evisceration, and chilling, each stage requires specialized equipment designed to minimize stress on the animal and maintain the quality of the meat.

Modern slaughterhouses are equipped with advanced machinery, such as stunning devices that render the animal unconscious before processing, automated evisceration lines, and chilling systems that rapidly cool the carcass to prevent spoilage. These technologies not only ensure humane handling but also meet stringent food safety standards, protecting consumers from potential health risks.

Moreover, meat processing equipment ranges from meat grinders and slicers to vacuum packaging machines and meat tenderizers. These tools are essential for transforming primal and subprimal cuts into consumer-ready portions, providing convenience for both commercial and home cooks.

Meat Science

Meat science encompasses the study of meat quality, microbiology, food safety, and preservation techniques. Understanding the science behind meat allows producers, butchers, and consumers to make informed decisions about meat sourcing, handling, and preparation.

Meat science also delves into the physiological and chemical changes that occur in meat during postmortem aging, which can significantly impact the tenderness and flavor of the final product. Additionally, advancements in meat science have led to the development of innovative processing methods, such as sous vide cooking and high-pressure processing, which can enhance the texture and safety of meat products.

By integrating knowledge of meat science into butchery practices and meat processing equipment, professionals can optimize meat quality and shelf life, meeting the demands of an increasingly discerning market.

Conclusion

From the traditional craft of butchery to the technological advancements in slaughter and processing equipment and the scientific insights of meat science, the world of meat processing is a rich tapestry of tradition, innovation, and expertise. By continually exploring and refining butchery techniques, investing in modern equipment, and staying informed about meat science, industry professionals can ensure the production of high-quality, safe, and flavorful meat products that meet the evolving needs of consumers.