Sausage making is a time-honored craft that combines traditional techniques with modern equipment and scientific principles. In this guide, we’ll explore the intricate processes of sausage making, the essential equipment required, and how it relates to meat slaughter and processing equipment as well as meat science.

Understanding Sausage Making Processes

The process of making sausages involves several key stages, including preparation, mixing, stuffing, and curing. Each stage contributes to the final flavor, texture, and quality of the sausages.

Preparation

The sausage-making journey begins with the selection of high-quality meats and the preparation of ingredients. This includes trimming the meat, grinding it to the desired consistency, and mixing in the appropriate seasoning and spices to create a distinct flavor profile.

Mixing

Once the ingredients are prepared, they are carefully mixed to ensure even distribution of flavors. The mixing process is crucial for achieving a balanced flavor and texture in the sausages.

Stuffing

After the mixing stage, the sausage mixture is carefully stuffed into casings to create the classic sausage shape. This step requires precision and attention to detail to ensure uniformity and proper filling of the casings.

Curing

Curing is an essential step in sausage making that allows the flavors to develop and intensify. This process may involve air-drying, smoking, or fermenting the sausages, depending on the desired final product.

Essential Equipment for Sausage Making

Successful sausage making relies on the use of specialized equipment that streamlines the process and ensures consistent results. The following are the key pieces of equipment used in sausage making:

Meat Grinder

A meat grinder is a fundamental tool for preparing the meat by grinding it to the desired texture. This equipment ensures the meat is evenly ground, which is crucial for the overall quality of the sausages.

Sausage Stuffer

A sausage stuffer is used to fill casings with the sausage mixture. This equipment allows for precise control over the stuffing process, ensuring uniform sausages with consistent fillings.

Smoker

Smoking is a traditional method of curing sausages, and a smoker is an essential piece of equipment for achieving the desired smoky flavor and preserving the sausages.

Curing Chamber

For fermented or air-dried sausages, a curing chamber provides the controlled environment necessary for the curing process. It regulates humidity and temperature to ensure the sausages mature properly.

Cutting and Packaging Equipment

Once the sausages are ready, cutting and packaging equipment is used to portion and package the sausages for distribution and sale, ensuring a professional presentation and preservation of quality.

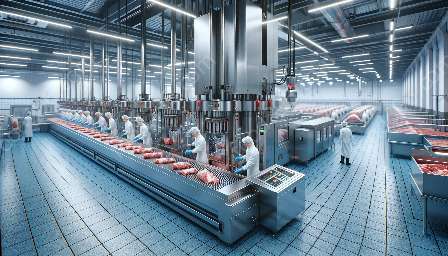

Compatibility with Meat Slaughter and Processing Equipment

Both sausage making and meat slaughter and processing require specialized equipment to maintain product quality, safety, and efficiency. The equipment used in meat slaughter and processing, such as carcass splitting saws, meat grinders, and vacuum sealers, can directly impact the raw materials available for sausage making.

For example, high-quality meat grindin

g equipment used in meat processing ensures that the ground meat prepared for sausages is consistent and free from contaminants, contributing to the overall safety and quality of the sausages.

Additionally, the proper handling and storage of meat obtained from the slaughter process, facilitated by equipment such as chilling and freezing systems, are essential for maintaining the freshness and quality of the meat used in sausage making.

The compatibility between sausage making and meat slaughter and processing equipment highlights the interconnectedness of these processes in the meat industry, emphasizing the importance of maintaining high standards throughout the entire supply chain.

Connection with Meat Science

Meat science plays a vital role in the art of sausage making, as it encompasses the scientific principles behind meat preservation, flavor development, and safety standards. Understanding the science of meat can significantly enhance the quality and consistency of sausages.

The principles of meat science, including meat composition, enzymatic reactions, and microbial activity, directly impact the techniques and processes used in sausage making. For example, knowledge of microbial activity and food safety standards is crucial to implementing effective curing and fermentation processes in sausage making.

The application of meat science also extends to the selection of meats, understanding the properties of different cuts, and leveraging technological advancements to optimize the sausage making process.

Conclusion

Sausage making is a blend of tradition, innovation, and scientific knowledge, requiring a deep understanding of processes, equipment, and the science of meat. By combining the art and science of sausage making, producers can create exceptional products that satisfy both culinary and scientific standards.