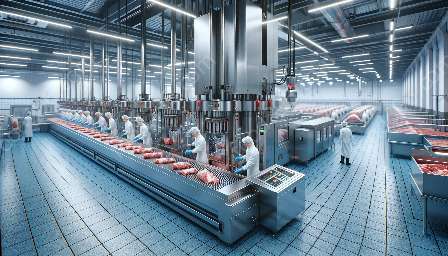

Meat chilling and freezing are crucial steps in the meat processing industry. In this guide, we will explore the various methods used to chill and freeze meat, their impact on the quality and safety of meat products, and their connection to meat science and slaughter and processing equipment.

The Importance of Chilling and Freezing in Meat Processing

Chilling and freezing are essential for preserving the quality and safety of meat products. These methods slow down bacterial growth and enzymatic activity, preventing spoilage and maintaining the freshness of meat.

Chilling Methods

There are several chilling methods commonly used in meat processing, including air chilling, water chilling, and vacuum chilling. Each method has its own benefits and limitations, and the choice of method depends on factors such as the type of meat, processing facility, and product quality requirements.

- Air Chilling: This method involves circulating chilled air around the meat to lower its temperature. Air chilling is known for preserving the natural flavor and texture of meat, as it does not introduce excess moisture.

- Water Chilling: In water chilling, meat is submerged in chilled water to lower its temperature. This method is efficient for rapid cooling and is commonly used in large-scale meat processing facilities.

- Vacuum Chilling: Vacuum chilling removes heat from the meat using a vacuum chamber. This method is effective for maintaining the appearance and juiciness of meat products.

Freezing Methods

Freezing is a widely used method for extending the shelf life of meat products. Rapid freezing helps to maintain the quality of meat by minimizing the formation of large ice crystals, which can damage the cellular structure of meat. Common freezing methods include blast freezing, cryogenic freezing, and plate freezing.

- Blast Freezing: In blast freezing, cold air is circulated at high velocities to quickly freeze meat products. This method is suitable for large quantities of meat and helps to preserve the texture and moisture content of the meat.

- Cryogenic Freezing: Cryogenic freezing involves the use of liquid nitrogen or carbon dioxide to rapidly freeze meat. This method is known for its speed and efficiency in achieving deep freezing temperatures.

- Plate Freezing: Plate freezing uses metal plates to freeze meat products. It is often used for individual cuts of meat and is effective in preserving the natural texture and flavor of the meat.

Meat Science and Chilling/Freezing Methods

The application of chilling and freezing methods is deeply connected to meat science, as these methods impact the physical, chemical, and microbiological properties of meat. Understanding the behavior of meat during chilling and freezing is essential for maintaining the quality of meat products.

Meat scientists study the effects of chilling and freezing on meat composition, texture, color, and shelf life. They also develop and optimize chilling and freezing methods to minimize quality loss and ensure food safety.

Connection to Slaughter and Processing Equipment

Effective chilling and freezing of meat products require the use of specialized equipment in slaughter and processing facilities. The design and operation of this equipment play a critical role in ensuring the quality and safety of meat products.

Slaughter and processing equipment such as chilling chambers, blast freezers, cryogenic freezers, and vacuum chillers are designed to provide precise temperature control and rapid cooling or freezing of meat. These technologies are continuously developed and improved to meet the evolving needs of the meat processing industry.

In conclusion, understanding the principles and applications of chilling and freezing methods is essential for anyone involved in the meat processing industry. By embracing the latest advancements in meat science, slaughter and processing equipment, and chilling/freezing technologies, the industry can continue to deliver high-quality, safe, and flavorful meat products to consumers.