Meat tumbling and massaging are crucial techniques in the realm of meat processing. Understanding the processes, equipment, and science behind these methods is essential for optimizing the quality and characteristics of meat products. This comprehensive guide delves into the intricacies of meat tumbling and massaging, their compatibility with meat slaughter and processing equipment, and their implications for meat science.

Meat Tumbling and Massaging Techniques Explained

Meat tumbling involves the use of specialized tumbling equipment to massage and marinate meat products. This process enhances the flavor, tenderness, and juiciness of the meat, ultimately improving its overall quality. The tumbling equipment typically consists of a rotating drum or tumbler that gently massages the meat with marinades, seasonings, and additives, ensuring thorough and even distribution.

Massaging, on the other hand, is a manual technique that involves applying pressure and kneading motions to the meat. This process helps break down the connective tissues and fibers, leading to improved texture and tenderness. Both tumbling and massaging techniques play a significant role in meat processing, contributing to the development of desirable meat characteristics.

Relevance to Meat Slaughter and Processing Equipment

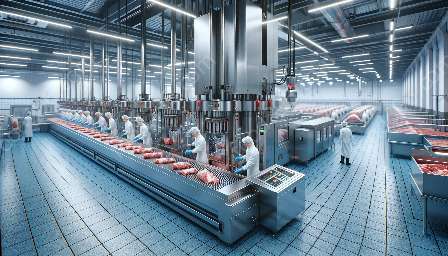

Meat tumbling and massaging techniques are closely intertwined with meat slaughter and processing equipment. The efficiency and effectiveness of these techniques depend on the quality and capabilities of the equipment used. Modern meat processing facilities are equipped with advanced tumblers, massagers, and marinating machines that are designed to optimize the tumbling and massaging processes.

For instance, meat tumbling equipment is equipped with adjustable speed and rotation settings to ensure precise control over the tumbling process. The tumblers also feature vacuum systems that aid in the absorption of marinades and flavors into the meat, resulting in uniform and consistent marination. Similarly, massaging equipment is designed with specific pressure and motion settings to achieve the desired meat texture and tenderness.

Furthermore, the integration of automation and technology in meat slaughter and processing equipment has revolutionized the tumbling and massaging processes. Automated control systems and sensors monitor factors such as temperature, pressure, and marination levels, ensuring optimal conditions for meat processing. This seamless integration between meat tumbling and massaging techniques and advanced equipment is pivotal in achieving high-quality meat products.

Impact on Meat Science

The application of meat tumbling and massaging techniques extends beyond their immediate effects on meat quality. These methods have a significant impact on meat science, encompassing aspects related to food chemistry, microbiology, and sensory evaluation. Scientists and researchers explore the underlying mechanisms of meat tumbling and massaging to comprehend their scientific implications.

From a chemical standpoint, meat tumbling and massaging influence the dispersion of marinades and additives within the meat matrix. This process alters the protein structures and interactions, leading to improvements in moisture retention, flavor retention, and texture modification. Moreover, the massaging of meat affects the distribution of fat and connective tissues, influencing the characteristics of the final meat product.

In the realm of microbiology, the marination process facilitated by meat tumbling equipment has implications for microbial safety and shelf life. The uniform distribution of antimicrobial agents and preservatives through tumbling ensures that bacteria and pathogens are effectively controlled, enhancing the microbial stability of meat products. Additionally, the controlled environment within the tumbling and massaging equipment minimizes the risk of cross-contamination, aligning with rigorous food safety standards.

Furthermore, sensory evaluation and consumer perception play a pivotal role in meat science. The enhanced tenderness, juiciness, and flavor resulting from tumbling and massaging techniques contribute to a positive sensory experience for consumers. Researchers conduct sensory analysis studies to gauge the impact of specific tumbling and massaging parameters on the overall eating quality of meat products, providing valuable insights for product development and consumer satisfaction.

Benefits and Applications of Meat Tumbling and Massaging

The utilization of meat tumbling and massaging techniques offers an array of benefits and diverse applications within the meat processing industry. These methods are instrumental in maximizing the quality, consistency, and yield of meat products, catering to the evolving demands of consumers and food businesses.

Benefits:

- Improved Flavor Profile: Tumbling and massaging enhance the absorption and distribution of marinades and seasonings, intensifying the flavor profile of meat products.

- Enhanced Tenderness and Texture: The mechanical action of tumbling and massaging breaks down the muscle fibers and connective tissues, resulting in tender and succulent meat.

- Moisture Retention: The marination process achieved through tumbling aids in retaining moisture within the meat, preventing dryness and enhancing juiciness.

- Consistent Marination: Tumbling equipment ensures uniform marination, eliminating variations in flavor and texture across different parts of the meat.

- Increased Production Efficiency: The automation and precision of tumbling and massaging equipment contribute to improved efficiency and throughput in meat processing facilities.

Applications:

- Marinated Meats: Tumbling and massaging are commonly utilized in the production of marinated meats such as barbecue, teriyaki, and citrus-infused products.

- Cured and Brined Products: These techniques play a vital role in the processing of cured and brined meats, ensuring optimal flavor penetration and curing effectiveness.

- Value-Added Cuts: Tumbling and massaging facilitate the enhancement of value-added meat cuts, allowing for the creation of premium, industry-specific products.

- Functional Meat Products: The application of tumbling and massaging extends to functional meat products incorporating specific ingredients for nutritional or functional purposes.

- Ready-to-Cook Products: These techniques are employed in the preparation of ready-to-cook meat products, offering convenience and flavor consistency for consumers.

Through these benefits and applications, meat tumbling and massaging techniques contribute to diversifying and enhancing the range of meat products available in the market, meeting the diverse preferences and requirements of consumers and culinary professionals.