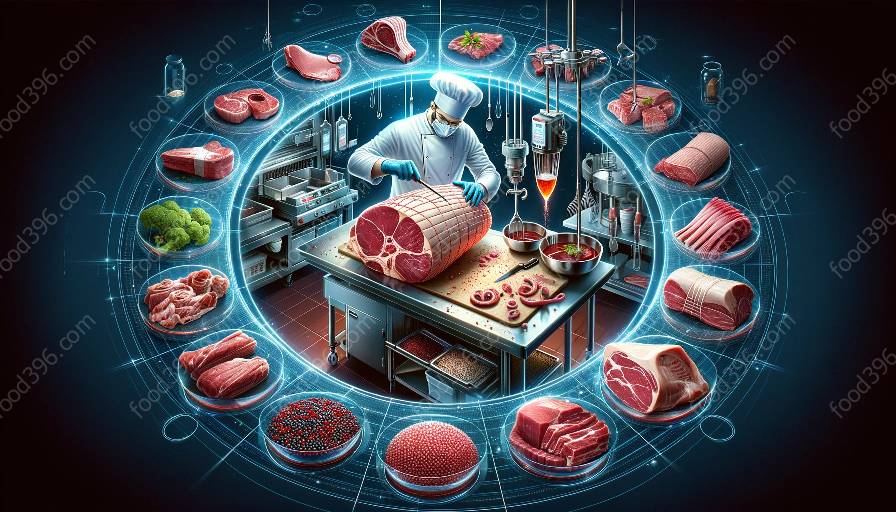

Meat production is a complex process that requires strict quality control measures to ensure the safety and hygiene of the meat products. This article discusses the importance of quality control in meat production and its compatibility with meat safety and hygiene and meat science.

Importance of Quality Control in Meat Production

Quality control in meat production is vital to ensure that the meat products meet the necessary safety and quality standards. It involves monitoring and managing the entire production process, from animal rearing to the final product packaging, to ensure that the meat is safe for consumption and of high quality.

Meat Safety and Hygiene

Meat safety and hygiene are crucial aspects of the meat production process. Quality control measures play a significant role in upholding the safety and hygiene standards in meat production facilities. These measures include regular sanitation, proper handling of meat, and adherence to strict hygiene protocols to prevent contamination and ensure the safety of consumers.

Meat Science

Meat science focuses on the study of meat properties, composition, and processing techniques to enhance the quality of meat products. Quality control in meat production complements meat science by ensuring that the scientific principles and techniques are applied throughout the production process to maintain the quality and safety of meat products.

Processes Involved in Quality Control

Quality control in meat production involves various processes and measures to maintain the desired standards. These include:

- Inspection of animals before slaughter to ensure they meet the required health and welfare standards.

- Monitoring the slaughtering process to ensure that it is carried out under hygienic conditions and that the meat is not contaminated.

- Testing for pathogens and contaminants in meat to prevent the distribution of unsafe products.

- Implementing strict temperature control and monitoring during storage, processing, and transportation to prevent spoilage and bacterial growth.

- Regular sanitation of equipment and facilities to maintain hygiene and prevent cross-contamination.

- Quality assessment of meat products based on sensory characteristics, nutritional content, and shelf-life.

Quality Assurance and Compliance

Quality assurance is a crucial aspect of quality control in meat production. It involves the implementation of standards, procedures, and protocols to ensure that the meat products consistently meet the desired quality and safety criteria. Compliance with regulatory requirements and industry standards is essential to instill consumer confidence and meet legal obligations.

Consumer Confidence and Expectations

Quality control measures in meat production play a significant role in maintaining consumer confidence and meeting their expectations. Consumers expect safe, high-quality meat products, and adherence to stringent quality control measures reassures them that the products they purchase are of the highest standards.

Technological Advances in Quality Control

Advancements in technology have revolutionized quality control in meat production. Automated monitoring systems, DNA testing for species identification, and rapid pathogen detection methods have enhanced the efficiency and accuracy of quality control measures, ensuring safer and higher quality meat products.

Conclusion

Quality control in meat production is a critical component of ensuring the safety, hygiene, and quality of meat products. It aligns with meat safety and hygiene principles and complements meat science by consistently maintaining the desired standards. Adopting comprehensive quality control measures is essential for sustaining consumer confidence and meeting regulatory requirements.