Fermentation is a natural process that has been harnessed by humans for centuries to produce various valuable products, such as food, beverages, and bio-based materials. In recent times, industrial scale fermentation processes have gained prominence for their efficiency and sustainability in meeting the demands of the food and beverage industry.

Understanding Fermentation

Fermentation is a metabolic process that converts sugar into acids, gases, or alcohol using microorganisms such as bacteria, yeast, or fungi. In an industrial context, fermentation involves the large-scale cultivation of microorganisms under controlled conditions to facilitate the production of various products.

Applications in the Food and Beverage Industry

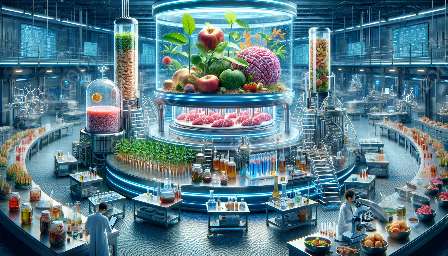

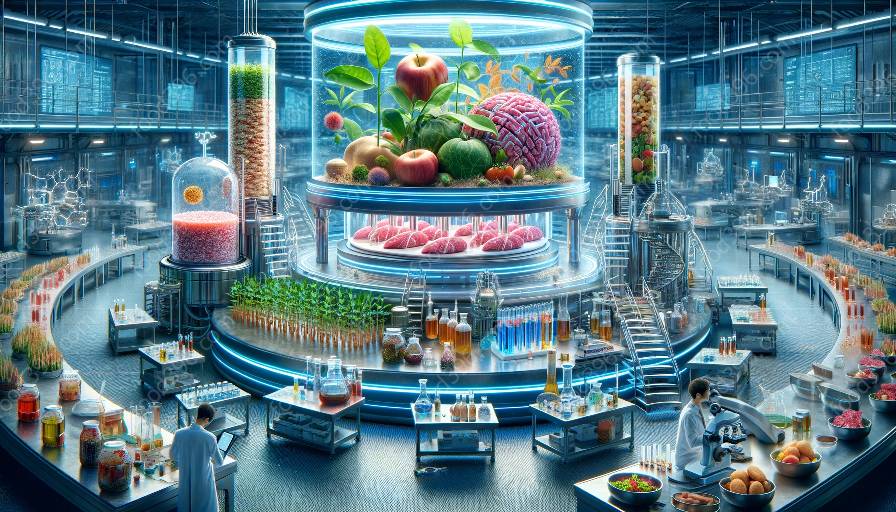

Industrial scale fermentation processes play a vital role in the food and beverage industry. They are used for the production of a wide range of products, including beer, wine, cheese, yogurt, soy sauce, vinegar, and bread. These processes help in enhancing the flavors, textures, and nutritional profiles of these food and beverage products.

Moreover, fermentation processes are crucial in the development of alternative and sustainable food sources, such as plant-based meat substitutes and dairy-free products. The use of fermentation in creating these products aligns with the growing consumer demand for more environmentally friendly and ethical food options.

Technology and Process

Industrial scale fermentation involves several key steps, including inoculation, fermentation, and product recovery. The process begins with the inoculation of a large bioreactor with the chosen microorganism. This is followed by the controlled fermentation of the microorganism in a nutrient-rich environment, where the desired product is synthesized.

Modern industrial fermentation processes utilize advanced bioreactor technologies, such as stirred tank reactors, airlift reactors, and fermenters with specialized control systems. These technologies ensure optimal growth conditions and product yield while minimizing energy consumption and environmental impact.

Environmental Impact

One of the key benefits of industrial scale fermentation processes is their potential to reduce the environmental impact of food and beverage production. Fermentation offers an eco-friendly alternative to traditional chemical synthesis methods, as it reduces the reliance on fossil fuels and minimizes greenhouse gas emissions.

Furthermore, the use of fermentation in producing plant-based and lab-grown food products can contribute to a more sustainable and ethical food industry. By reducing the environmental footprint of food production, industrial scale fermentation processes support the transition towards a more environmentally conscious and resource-efficient food system.

Food Biotechnology and Fermentation

Fermentation processes are at the forefront of food biotechnology, a field that explores the application of biological systems for food production and processing. Food biotechnologists leverage the principles of fermentation to develop innovative and sustainable solutions for the food and beverage industry.

Advancements in food biotechnology have led to the creation of novel fermentation-based food products, optimized production strains, and tailored fermentation processes that cater to specific nutritional and sensory requirements. These developments contribute to the diversification and enhancement of the food and beverage market, offering consumers an array of healthier, tastier, and more sustainable options.

The integration of food biotechnology with industrial scale fermentation processes is driving a paradigm shift in the food industry, fostering innovation, sustainability, and the responsible utilization of natural resources.