Fermentation is a captivating process that plays a crucial role in the production of vinegar. This article will guide you through the science, processes, and applications related to fermentation in the context of vinegar production, the food and beverage industry, and food biotechnology.

The Science of Fermentation in Vinegar Production

Fermentation in vinegar production involves the conversion of sugars into acetic acid by acetic acid bacteria. This transformation occurs through a series of bio-chemical reactions that are initiated and controlled by specific microorganisms under controlled conditions.

One of the key microorganisms involved in vinegar fermentation is Acetobacter. These bacteria utilize the ethanol produced from the initial fermentation of sugars and convert it into acetic acid, the main component of vinegar. The process of vinegar fermentation is a delicate balance of factors such as temperature, oxygen levels, and nutrient availability, all of which influence the activity and growth of the acetic acid bacteria.

The conversion of sugars into acetic acid is achieved through a two-step process. First, the sugars are converted into alcohol by yeast in an anaerobic environment. Subsequently, the acetic acid bacteria oxidize the alcohol into acetic acid in an aerobic environment. The entire process of vinegar fermentation is a fascinating example of microbial cooperation and metabolic diversity.

Processes Involved in Vinegar Fermentation

Vinegar fermentation typically involves two major steps: the alcoholic fermentation of sugars and the acetic acid fermentation of alcohol. In the first step, yeasts ferment the sugars present in the raw material, such as fruits or grains, into alcohol under anaerobic conditions. This creates the necessary substrate for the acetic acid bacteria to carry out the second step of the fermentation process.

The raw material used in vinegar production can vary, leading to the production of different types of vinegar. For instance, apple cider vinegar is produced from the fermentation of apple cider, while wine vinegar is derived from the fermentation of wine. The type of raw material and the specific strains of microorganisms involved can significantly influence the flavor, aroma, and overall quality of the resulting vinegar.

In commercial vinegar production, the fermentation process is carefully controlled to ensure consistent quality and safety. The production facilities are designed to provide the ideal conditions for the growth and activity of the microorganisms involved, including precise temperature control, oxygen supply, and nutrient management. These controlled environments allow for efficient and predictable fermentation, resulting in high-quality vinegar products.

Applications of Fermentation in the Food and Beverage Industry

Fermentation has been utilized for centuries in the food and beverage industry to produce a wide range of products such as bread, beer, cheese, yogurt, and, of course, vinegar. The unique flavors, textures, and nutritional properties of fermented foods and beverages are a result of the diverse metabolic activities of microorganisms during fermentation.

In the case of vinegar, fermentation not only imparts a distinct sour taste but also contributes to its preservation and culinary uses. Vinegar is a versatile ingredient that is used in various culinary applications, including pickling, salad dressings, marinades, and as a natural preservative for certain food products. The diverse range of vinegars available, such as balsamic vinegar, rice vinegar, and malt vinegar, reflects the impact of different fermentation processes and raw materials on the final product.

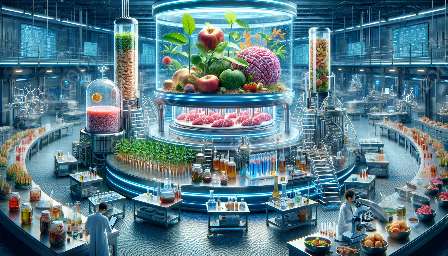

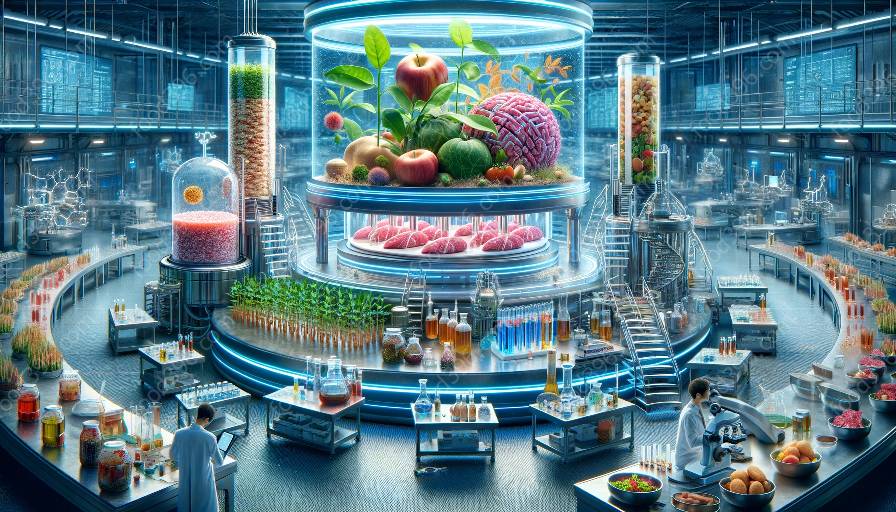

Furthermore, fermentation is increasingly being recognized for its role in the development of novel and sustainable food products. The use of fermentation in food biotechnology allows for the creation of functional foods, nutraceuticals, and food additives with enhanced nutritional profiles and health benefits. This innovative approach to food production holds great promise for addressing global challenges related to food security and sustainability.

Fermentation and Food Biotechnology

Food biotechnology leverages the principles of fermentation to develop new food products, enhance food preservation, and improve food quality and safety. The application of biotechnological techniques in fermentation processes has led to advancements in food science and technology, paving the way for the creation of innovative food ingredients and formulations.

One area of particular interest is the use of microbial fermentation to produce valuable compounds with potential health-promoting effects. Probiotics, for example, are live microorganisms that confer health benefits when consumed in adequate amounts, and they are commonly produced through carefully controlled fermentation processes. The development of novel probiotic strains and the exploration of their diverse applications in functional foods and dietary supplements are areas of active research within the field of food biotechnology.

Moreover, food biotechnology encompasses the optimization of fermentation processes to maximize efficiency, reduce waste, and minimize environmental impact. By harnessing the power of microorganisms and their metabolic capabilities, biotechnologists are able to design sustainable and eco-friendly solutions for food production and waste management.