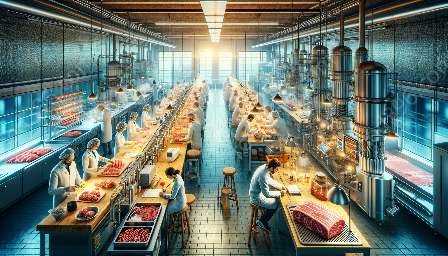

Meat product packaging and preservation play a crucial role in the meat industry, ensuring the safety, quality, and shelf life of meat products. From innovative technologies to traditional preservation methods, the field of meat product packaging and preservation is constantly evolving to meet the demands of the modern market. In this article, we will explore the intricate relationship between meat product packaging and preservation, as well as its compatibility with meat product development and meat science.

The Importance of Meat Product Packaging and Preservation

Meat product packaging and preservation are essential components of the meat industry, as they directly impact the quality, safety, and shelf life of meat products. Effective packaging and preservation methods help prevent spoilage, maintain freshness, and ensure that meat products reach consumers in optimal condition.

Proper packaging also plays a critical role in protecting meat products from physical damage and contamination, thereby safeguarding against foodborne illnesses and ensuring consumer confidence. Preservation techniques, on the other hand, are crucial for extending the shelf life of meat products, reducing waste, and facilitating global distribution.

Link to Meat Product Development

The relationship between meat product packaging and preservation and meat product development is deeply intertwined. As meat product developers strive to create new and innovative meat products, they must consider the packaging and preservation methods that will best preserve the desired attributes of their products.

Understanding the interactions between ingredients, packaging materials, and preservation techniques is crucial for successful meat product development. It involves careful consideration of factors such as oxygen and moisture levels, temperature control, and microbial safety to ensure the stability and quality of the final meat products.

Advancements in Meat Science

Meat science encompasses the study of meat products from farm to table, focusing on aspects such as meat quality, safety, and sustainability. In recent years, advancements in meat science have led to the development of new packaging and preservation technologies aimed at enhancing the overall quality and safety of meat products.

Emerging research in meat science has fueled the creation of packaging materials with enhanced barrier properties, intelligent packaging solutions, and novel preservation methods that minimize the use of additives and preservatives. These developments not only contribute to the advancement of the meat industry but also align with the growing consumer demand for more natural and sustainable meat products.

Technological Innovations and Methods in Meat Product Packaging and Preservation

The landscape of meat product packaging and preservation is continually evolving, driven by technological innovations and a growing emphasis on sustainability and food safety. Some of the notable advancements in the field include:

- Vacuum Packaging: This method involves removing air from the packaging to create an oxygen-free environment, thereby slowing down the microbial growth and oxidation processes that can lead to spoilage.

- Modified Atmosphere Packaging (MAP): MAP involves altering the atmospheric composition within the packaging to extend shelf life and maintain product quality. By controlling the levels of oxygen, carbon dioxide, and nitrogen, MAP helps preserve the freshness of meat products.

- Active and Intelligent Packaging: These cutting-edge packaging solutions incorporate active components, such as oxygen scavengers and antimicrobial agents, to actively extend shelf life and improve product safety. Intelligent packaging, equipped with sensors and indicators, provides real-time information about the condition of the packaged meat products.

- Natural Preservatives: The use of natural preservatives, such as plant extracts and essential oils, has gained traction as a safer and more consumer-friendly alternative to synthetic preservatives. These natural compounds exhibit antimicrobial properties, effectively extending the shelf life of meat products.

- High-Pressure Processing (HPP): HPP is a non-thermal preservation technique that uses high pressure to inactivate spoilage microorganisms while preserving the nutritional and sensory qualities of meat products. This method is increasingly being adopted for its ability to extend shelf life without the use of heat or chemical additives.

Environmental Sustainability and Packaging Innovations

As the meat industry continues to address sustainability challenges, a growing focus has been placed on developing environmentally friendly packaging solutions. Biodegradable and compostable packaging materials, as well as initiatives to minimize packaging waste, are increasingly becoming key considerations in meat product packaging and preservation.

Additionally, advancements in packaging design and engineering aim to optimize the use of resources, reduce carbon footprints, and enhance recyclability. These efforts align with the broader goal of creating a more sustainable and resource-efficient meat supply chain.

Future Trends and Considerations

Looking ahead, the future of meat product packaging and preservation is poised for further innovation and evolution. Key areas for future consideration include:

- Smart Packaging Technologies: Integration of smart sensors and Internet of Things (IoT) platforms to enable real-time monitoring and traceability of meat products throughout the supply chain.

- Nanotechnology Applications: Utilization of nanomaterials for enhanced barrier properties, antimicrobial coatings, and improved shelf life extension, while ensuring safety and regulatory compliance.

- Circular Economy Practices: Implementation of circular economy principles to promote the reuse, recycling, and regeneration of packaging materials within the meat industry, reducing waste and environmental impact.

- Consumer-Centric Packaging: Customizable and convenient packaging solutions that cater to changing consumer lifestyles, preferences, and demand for personalized portioning and convenience.

Conclusion

Meat product packaging and preservation are central to the development and advancement of the meat industry, intersecting with meat product development and meat science to uphold quality, safety, and sustainability. As technology, science, and consumer preferences continue to shape the landscape of meat products, ongoing innovation and collaboration across these domains will drive the future of meat product packaging and preservation.