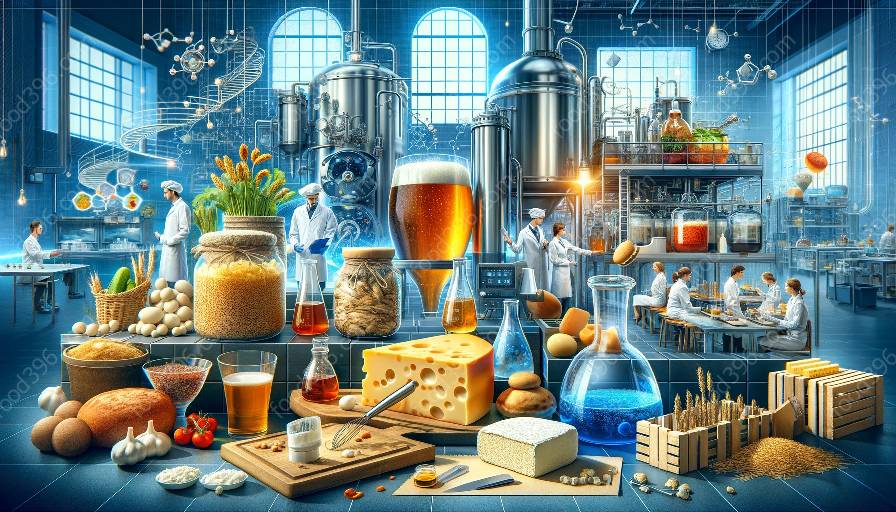

Fermentation is a crucial process in the food and drink industry, involving the controlled use of microorganisms to produce valuable products. In the context of industrial fermentation, this science plays a key role in the production of various food and beverage items, ranging from beer and wine to cheese, yogurt, and many others.

The Science of Fermentation

Fermentation, at its core, is a metabolic process that converts carbohydrates, such as sugars and starches, into alcohols, acids, or gases using microorganisms such as bacteria, yeast, or fungi. This process occurs in an anaerobic environment and is well-known for its ability to preserve food, enhance flavors, and provide health benefits.

The main microorganisms involved in industrial fermentation are bacteria and yeast. Bacteria are typically used to produce specific types of food products, such as cheese, yogurt, and sauerkraut, while yeast is commonly employed in the production of alcoholic beverages like beer and wine. Understanding the behavior and metabolic pathways of these microorganisms is crucial for optimizing the fermentation process.

Fermentation science encompasses the study of these microorganisms, their interactions with substrates, and the environmental conditions needed for their optimum growth and product formation. Researchers and scientists in the field of fermentation science work to improve fermentation processes, develop new products, and address challenges related to production efficiency, consistency, and quality.

Applications of Industrial Fermentation in Food & Drink

Industrial fermentation has a wide range of applications in the food and drink industry. One of the most well-known examples is the production of alcoholic beverages such as beer, wine, and spirits. The fermentation process in brewing and winemaking involves the conversion of sugars from grains or fruits into alcohol and carbon dioxide, resulting in the characteristic flavors and aromas of the final products.

In addition to alcoholic beverages, fermentation is also essential in the production of dairy products. The transformation of milk into products like yogurt, cheese, and kefir relies on the activity of lactic acid bacteria in controlled fermentation processes. The microorganisms involved in these processes contribute to the unique textures and flavors of the final dairy products.

Moreover, fermentation is used in the production of various condiments and sauces, such as soy sauce, vinegar, and kimchi. These products undergo fermentation to develop their distinct tastes and aromas, as well as to improve their shelf life through natural preservation methods.

Benefits of Industrial Fermentation

Industrial fermentation offers numerous benefits for the food and drink industry, including improved product quality, enhanced nutritional value, and extended shelf life. By harnessing the power of microorganisms, food and beverage producers can create a diverse range of products with unique flavors and textures, appealing to different consumer preferences.

Furthermore, fermentation can contribute to the development of functional foods and beverages that offer health benefits beyond basic nutrition. Probiotic-rich fermented products, for example, can support gut health and boost the immune system, leading to increased consumer interest in these items.

From a sustainability perspective, industrial fermentation can also help minimize food waste by utilizing raw materials more efficiently and by preserving perishable ingredients through fermentation processes. This aligns with the growing emphasis on sustainable practices in the food and drink industry.

Challenges in Industrial Fermentation

While industrial fermentation offers numerous advantages, it also presents challenges that need to be addressed. One of the key challenges is maintaining process control and consistency, especially in large-scale fermentation operations. Fluctuations in environmental conditions, such as temperature and pH, can impact the growth and activity of microorganisms, affecting the quality and yield of the final products.

In addition, the risk of contamination from undesirable microorganisms poses a constant challenge in industrial fermentation. Maintaining strict hygiene and sanitation practices is essential to prevent spoilage and ensure the safety of fermented food and drink products.

Furthermore, scaling up fermentation processes from laboratory or small-scale settings to industrial production can introduce new complexities, including the need for specialized equipment, efficient nutrient supply, and waste management. Addressing these challenges requires collaboration between fermentation scientists, food technologists, and engineering experts to optimize the entire production chain.

Future Perspectives and Innovations in Fermentation Science

As the food and drink industry continues to evolve, fermentation science is poised to play a pivotal role in driving innovation and sustainability. Advances in bioprocessing technologies, genetic engineering of microorganisms, and the exploration of novel fermentation substrates are expanding the possibilities for creating novel food and beverage products that cater to changing consumer demands.

Moreover, the integration of fermentation with other emerging fields such as biotechnology, nutraceuticals, and alternative protein sources presents opportunities to develop a new generation of fermented products with enhanced nutritional profiles, improved functionality, and reduced environmental impact.

By embracing interdisciplinary approaches and leveraging cutting-edge research, the future of industrial fermentation holds promise for revolutionizing the food and drink landscape, offering consumers a wide array of innovative, sustainable, and health-promoting fermented products.