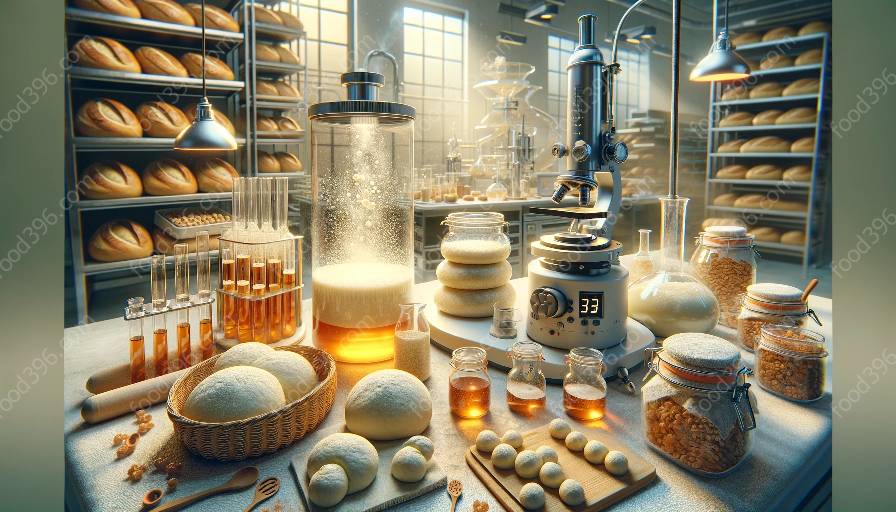

Have you ever wondered how bakers achieve those perfectly risen loaves with a light and airy texture? The answer lies in the art and science of dough proofing techniques, bread fermentation, and dough development. In this guide, we'll explore everything you need to know about these critical aspects of baking, as well as the underlying baking science and technology.

Dough Proofing Techniques

Dough proofing is a crucial step in the bread-making process that allows the dough to rise, develop flavor, and achieve the desired texture. Several techniques can be used to proof dough, each with its unique benefits and effects on the final product.

1. Room Temperature Proofing

This is the most common method of dough proofing, where the dough is left at room temperature to rise. The optimal temperature for room temperature proofing is around 75°F to 85°F, as it allows the yeast to ferment the dough at a moderate pace, resulting in a well-developed flavor and texture.

2. Refrigerator Proofing

Refrigerator proofing involves placing the dough in the refrigerator to proof at a much slower pace. This extended proofing time allows for more complex flavor development and can also improve the dough's handling characteristics.

3. Proofing Box or Proofer

A proofing box or proofer provides a controlled environment for proofing dough at a consistent temperature and humidity. This method is especially useful for commercial bakeries or home bakers who want precise control over the proofing process.

Bread Fermentation and Dough Development

Bread fermentation is the process by which yeast and bacteria break down the carbohydrates in the dough, producing carbon dioxide, alcohol, and organic acids. This gas production causes the dough to rise and develop a light and airy texture. Fermentation also contributes to the development of complex flavors in the bread.

The timing and temperature of the fermentation process have a significant impact on the final product. Longer fermentation at lower temperatures allows for more flavor development and improved texture, while shorter fermentation at higher temperatures can result in a faster rise but may not develop as much flavor.

Dough Development

Dough development refers to the physical and chemical changes that occur in the dough during mixing and fermentation. Proper dough development is essential for achieving the desired texture and structure in the final baked product.

During fermentation, yeast and enzymes in the dough break down the proteins and starches, creating a network of gluten and a well-structured crumb. The kneading and folding of the dough also play a crucial role in developing its strength and elasticity.

Baking Science & Technology

Understanding the science and technology behind baking is essential for mastering the art of breadmaking. Factors such as oven temperature, steam injection, and dough hydration all influence the final outcome of the baked product.

Oven spring, the initial burst of rising that occurs in the first few minutes of baking, is influenced by the oven's temperature and the ability of the dough to expand before the structure sets. Steam injection in the oven can help create a crisp and shiny crust by delaying the setting of the crust and allowing for a more significant rise.

Additionally, the hydration level of the dough affects its handling characteristics and the texture of the final bread. Higher hydration dough tends to create a more open and airy crumb, while lower hydration dough produces a denser, chewier texture.

With a deeper understanding of these baking principles, you can fine-tune your dough proofing techniques to achieve the perfect loaf of bread.